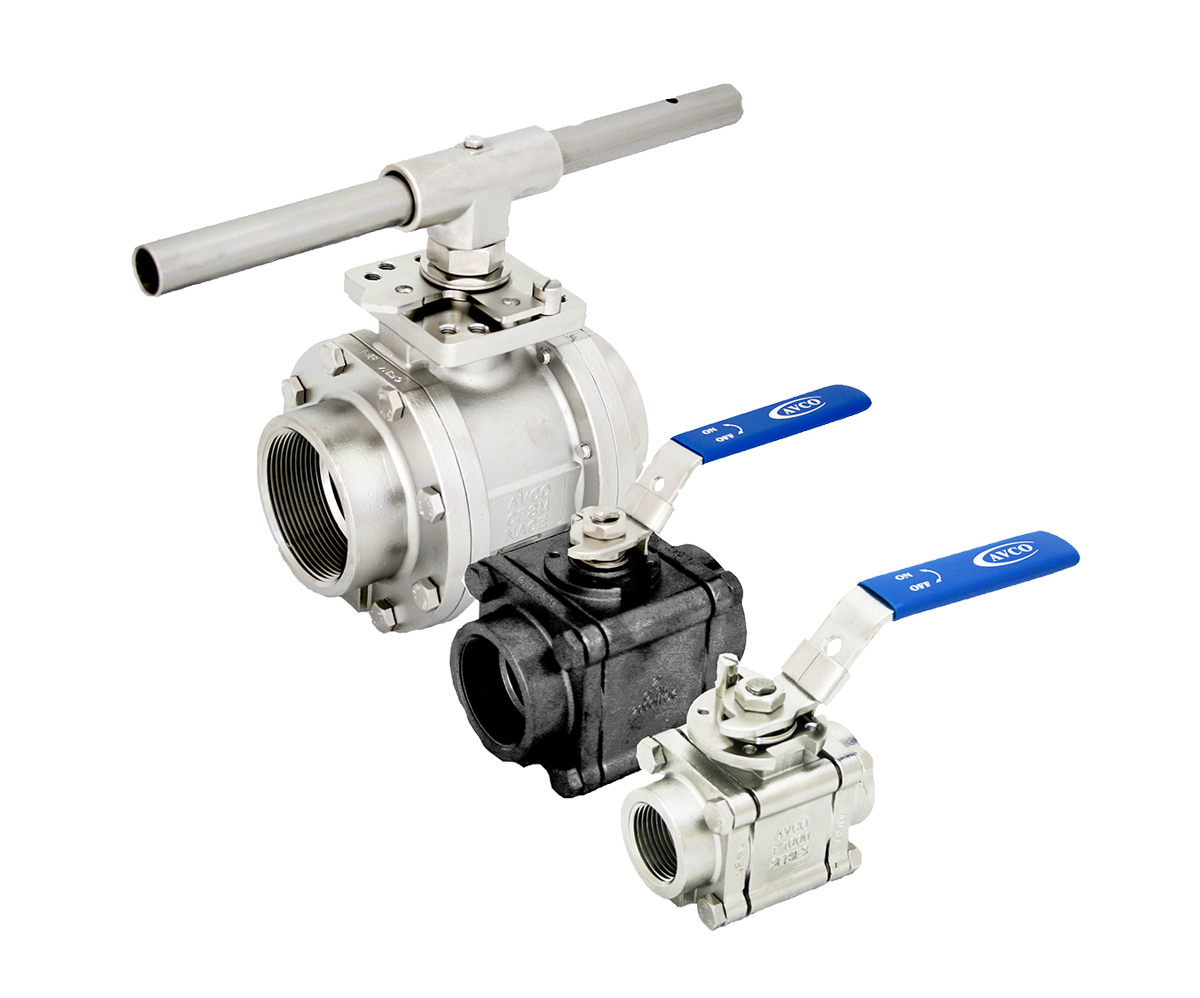

Description

The AVCO 1100 series ball valve is designed in house made for high performance and quality. The investment cast, precision machined, 3-piece design gives great flexibility for butt weld, socket weld, NPT, BSP and flanged ends up to ANSI class 600 or 2000 WOG. With regards to ASME B16.34, the valves meet or exceed all design standards and are fully tested to API 598. Materials of construction are stainless steel, carbon steel and various alloys including Hastelloy, Alloy 20, Monel & Inconel. The floating full port ball lies between seats encapsulated in metal retainer rings. The encapsulation of the seat also gives an option for fire safe trim that meets API 607. Seats are available in TFE, RTFE, CTFE, UHMWPE, PEEK and Stellite metal to satisfy harsh environment and high temperature applications. The stem is live loaded with blow out prevention and has online adjustment capability. Sealing occurs at the thrust washer inside the body to reduce the potential for leakage. The ISO 5211 mount pad allows for many actuator styles (electric, pneumatic, etc.) to be mounted with ease. Whether for use in the oil, gas, chemical or steam industry, this valve will deliver performance, quality and ease of use.